Market Overview

The metallurgical additives market encompasses the industry segment that focuses on the production and supply of various additives used in metallurgy. Metallurgical additives are substances added to metals during the melting, refining, or casting processes to enhance their properties, improve process efficiency, or achieve desired chemical compositions. These additives can include elements like alloys, fluxes, deoxidizers, grain refiners, and modifiers. The market caters to a wide range of applications in the metal industry, including steel, aluminum, copper, and other non-ferrous metal production. The metallurgical additives market is estimated to grow at a CAGR of 6.1% from 2024 to 2032. The metallurgical additives market is a critical component of the broader metal production and processing industry. It plays a vital role in determining the quality and characteristics of the final metal products. The demand for these additives is driven by the need for high-quality metals in various industries such as automotive, aerospace, construction, and electronics. Additives are crucial for enhancing metal properties like strength, ductility, corrosion resistance, and thermal conductivity.

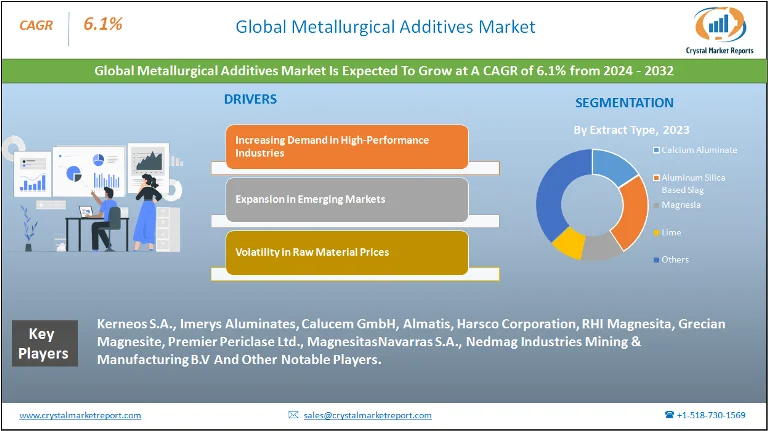

Metallurgical Additives Market Dynamics

Driver: Increasing Demand in High-Performance Industries

A significant driver for the metallurgical additives market is the escalating demand from high-performance industries like aerospace, automotive, and electronics. These sectors require metals with superior properties such as enhanced strength, lightweight, improved conductivity, and resistance to extreme conditions. Metallurgical additives play a crucial role in achieving these characteristics. For instance, in the aerospace industry, the demand for lightweight yet strong metals has led to increased use of specialized additives in aluminum alloys to improve their strength-to-weight ratio. Similarly, in the automotive sector, the push towards fuel efficiency and emission reduction has spurred the demand for advanced steel and aluminum additives to produce lighter, stronger, and more durable components.

Opportunity: Expansion in Emerging Markets

A notable opportunity for the metallurgical additives market lies in the expansion into emerging markets. Countries in Asia, Africa, and South America are experiencing rapid industrialization and urbanization, leading to increased demand for metals in construction, infrastructure, and manufacturing. This growth provides a significant opportunity for the market, as these regions seek advanced metallurgical technologies to improve their metal production capabilities. The rising construction activities in these regions, necessitating large quantities of high-quality steel and aluminum, are indicative of the potential market expansion.

Restraint: Volatility in Raw Material Prices

A major restraint for the metallurgical additives market is the volatility in raw material prices. Many additives are derived from elements that are subject to price fluctuations due to changes in global supply and demand, geopolitical factors, and environmental regulations. This price volatility can affect the cost-effectiveness of metal production and, consequently, the demand for certain additives. For example, the fluctuating prices of rare earth elements, which are crucial for certain high-performance alloys, pose a significant challenge for steady market growth.

Challenge: Environmental and Regulatory Challenges

The metallurgical additives market faces a critical challenge in terms of environmental impact and regulatory compliance. The production and use of some additives can have significant environmental repercussions, including pollution and resource depletion. Additionally, the industry is subject to stringent environmental regulations, which can vary widely across different regions and can impact the market dynamics. For instance, the increasing focus on reducing greenhouse gas emissions and waste in metal production processes is leading to a greater demand for more sustainable and eco-friendly additive solutions. The challenge lies in developing additives that not only meet the performance requirements but also comply with environmental standards.

Market Segmentation by Type

In the metallurgical additives market, segmentation by type includes Calcium Aluminate, Aluminum Silica Based Slag, Magnesia, Lime, and Others. Among these, Calcium Aluminate is expected to register the highest Compound Annual Growth Rate (CAGR) from 2024 to 2032. This growth can be attributed to its increasing use in high-performance steelmaking, where it enhances the refining process and improves the quality of steel. Calcium Aluminate is particularly valued for its ability to control sulfide and oxide inclusions in steel, leading to improved mechanical properties and machinability. On the other hand, the highest revenue in 2023 was generated by Aluminum Silica Based Slag. This segment's dominance is due to its widespread application in iron and steel manufacturing as a flux agent. Aluminum Silica Based Slag plays a critical role in the removal of impurities, assisting in the production of cleaner and higher-quality metals, which is essential in various industries.

Market Segmentation by End-use

Regarding market segmentation by end-use, the categories include Automotive, Aerospace, Electronics, Medical, Energy, Building & Construction, and Others. The Aerospace sector is projected to experience the highest CAGR from 2024 to 2032. This growth is driven by the increasing demand for advanced materials with enhanced properties like high strength-to-weight ratio and corrosion resistance, essential for aerospace applications. Metallurgical additives are crucial in achieving these properties, leading to their growing use in aerospace material manufacturing. Conversely, the Automotive sector accounted for the highest revenue in 2023. The automotive industry relies heavily on metallurgy for the production of various components and structures. The demand for lightweight, durable, and high-performance metals in the automotive sector, especially with the growing trend towards electric and hybrid vehicles, underscores the significance of metallurgical additives in this industry.

Market Segmentation by Region

In the geographic segmentation of the metallurgical additives market, diverse trends are observed across different regions, with each region exhibiting unique characteristics in terms of market dynamics. The Asia-Pacific region, particularly countries like China and India, is expected to witness the highest Compound Annual Growth Rate (CAGR) from 2024 to 2032. This anticipated growth is largely due to rapid industrialization, urbanization, and the increasing demand from end-use sectors like automotive, construction, and aerospace in these emerging economies. The region's expansive manufacturing base, coupled with growing investments in infrastructure and technological advancements, positions it as a key growth area for the metallurgical additives market. In contrast, in 2023, the highest revenue was generated by North America, attributed to its advanced industrial sector, well-established automotive and aerospace industries, and stringent quality standards necessitating high-performance metals. North America's leading position in the market is also supported by the presence of key market players and advanced research and development capabilities in metallurgical technologies.

Competitive Trends

In terms of competitive trends and top players in the market, companies like Kerneos S.A., Imerys Aluminates, Calucem GmbH, Almatis, Harsco Corporation, RHI Magnesita, Grecian Magnesite, Premier Periclase Ltd., MagnesitasNavarras S.A., Nedmag Industries Mining & Manufacturing B.V. were among the leading participants in 2023. These companies have established a strong market presence through diverse strategies, including product innovation, strategic partnerships, and global expansion. Vesuvius, for example, has been focusing on developing advanced metallurgical additives that offer enhanced performance and environmental benefits. Harsco Corporation has been investing in research and development to introduce innovative solutions in the market. These companies are expected to continue their focus on innovation, sustainability, and market expansion from 2024 to 2032. Their strategies are anticipated to include further advancements in product technology, exploring new applications in emerging markets, and adhering to environmental regulations. The combined revenues of these companies in 2023 reflect their dominance in the market, and their ongoing strategies are expected to significantly influence the market trends and dynamics over the forecast period. This competitive landscape highlights a market driven by technological advancements, globalization, and the need to meet the evolving demands of diverse end-use industries.